Revolutionary Housing Material Sets New Benchmark

Pioneering innovative lighting solutions is our passion. New materials unlock luminaire performance to weight ratios never before possible. We now manufacture ultra-light but robust and highly durable products with benchmark light performance.

The revolutionary plastic ceramic materials with outstanding thermal performance open a world of possibilities never thought achievable only a few years ago. The replacement of metal based housing heat-sinks with thermally conductive plastic not only opens a myriad of design options, but also means complete corrosion resistance. This is especially important in demanding environmental conditions such as the corrosive salt laden marine environment where lights are constantly exposed to the elements and sometimes temporarily submerged.

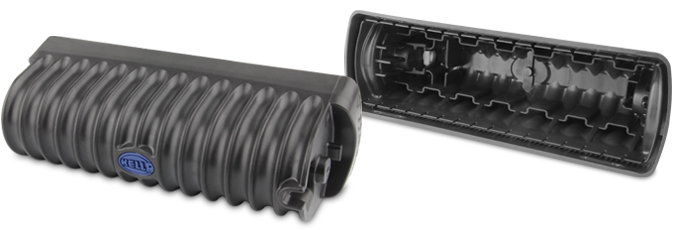

|

| WL1300 Housing Featuring Thermally Conductive Plastic |

Less metal also means less weight: Lamps with thermally conductive plastic are up to 60% lighter than comparable metal bodied lamps. The much lower mass significantly reduces the stress on mounting points in high vibration and shock applications.

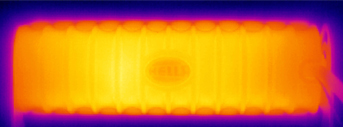

| Outstanding Thermal Performance | ||

| A lamp housing made from thermally conductive plastic works much the same as the previously used metal housing. The innovative ceramic based plastic transfers the heat generated by the LED’s and drive electronic to the outside of the lamp body, thereby lowering the internal thermal stress on the component. This in turn ensures a long service life with minimal degradation of the LED’s. |  |

|

|

At HELLA we use CoolPoly® for our thermally conductive lamp housings, which is some 30 times more conductive than conventional plastic. |

||